Overview

Build to Specification (BTS) is a manufacturing and engineering approach where products, components, or systems are designed and developed based on precise client-defined parameters. This method ensures that businesses receive tailor-made solutions that meet their exact operational and performance requirements.

By partnering with Optimized Solutions, organizations can streamline operations, reduce overhead costs, and ensure the delivery of high-quality, precision-engineered components. Our team of experts specializes in Build to Specification projects, providing tailored solutions that meet your exact requirements. From concept to prototype and full-scale production, we accelerate development cycles, transforming your vision into reality with efficiency, innovation, and technical excellence.

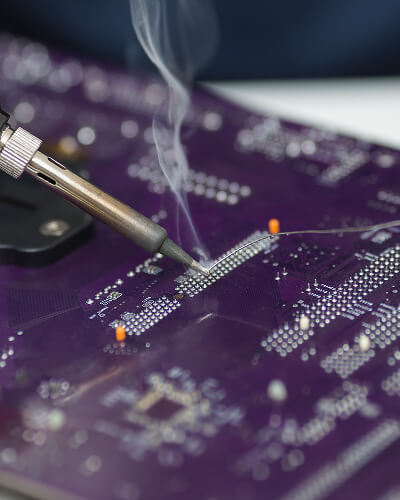

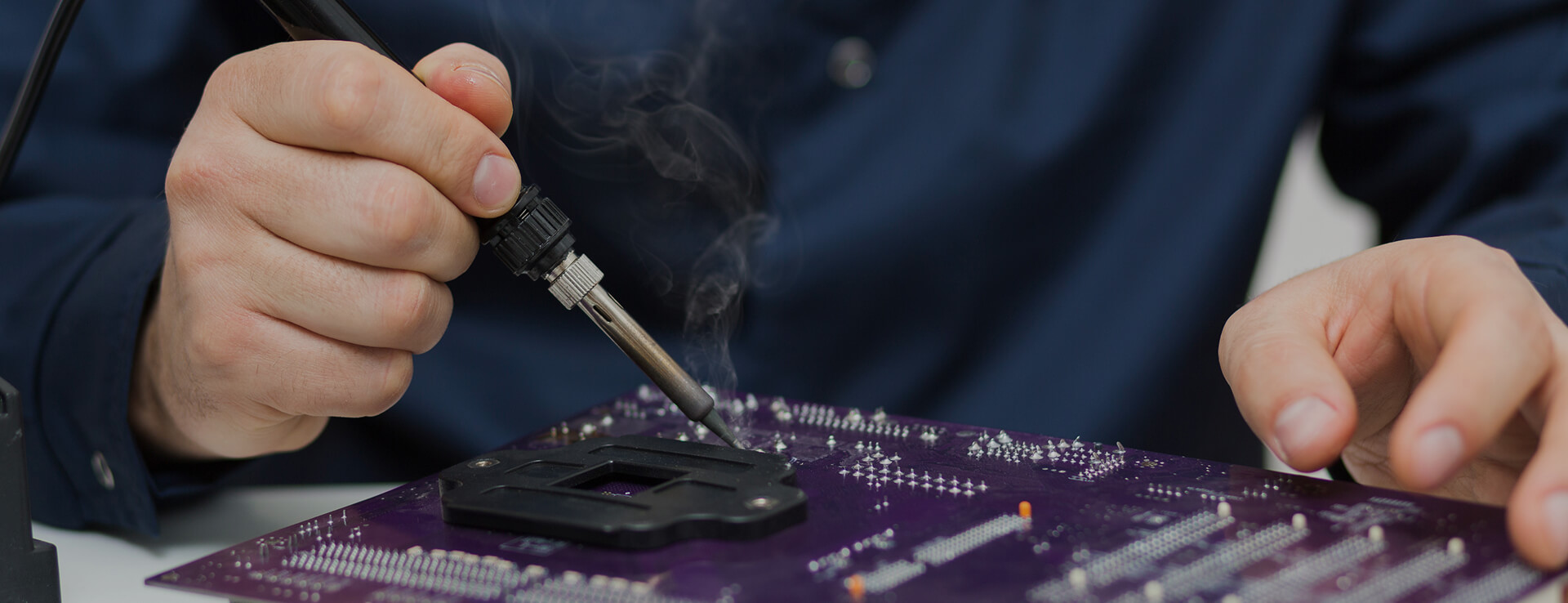

Custom Electronics

Custom Electronics

Digital Transformation

Digital Transformation

Test Measurement & Control

Test Measurement & Control

Our Products

Our Products

New Product Development

New Product Development Build To Print

Build To Print Build-to-Spec Custom Electronics

Build-to-Spec Custom Electronics Learn More

Learn More