- Home

- About Us

- Our Offerings

-

Custom Electronics

Custom Electronics

Digital Transformation

Digital Transformation

Industry 4.0 Apps

Custom Development

Deployment

Test Measurement & Control

Test Measurement & Control

Automated Test Equipment

Control Systems

Learn More

-

- Who We Serve

- Careers

- Insights

- Contact Us

While equipment aging and deterioration are inevitable, significant losses can be avoided by identifying and addressing the factors leading to failure. Many industry applications are complex and, without automation testing, would be difficult to test effectively. These automated tests require regular maintenance and debugging, and if they fail, troubleshooting the entire process becomes a daunting, expensive, and time-consuming task.

Often, the process must be repeated multiple times to pinpoint the root cause of the failure. Even a small change in the application can break the test, requiring a complete restart of the entire procedure. Additionally, lacking a comprehensive maintenance program can lead to higher insurance premiums and increased operational costs.

An effective maintenance testing program is crucial in preventing equipment failures while ensuring the efficiency and reliability of systems and facilities. It guarantees smooth operations and seamless execution without compromising safety, while also identifying critical hotspots that require immediate attention.

we deliver expertly managed maintenance testing solutions tailored to your needs. By integrating products and insights, we help you avoid hardware failures, save time, reduce the labor required for troubleshooting, minimize costly breakdowns, and lower the risk of unplanned outages.

We take pride in having successfully provided the following testing equipment and corresponding measurement methods to support the industry’s most demanding needs.

Maintenance Testing is a software testing process that ensures applications continue to function correctly after modifications such as bug fixes, updates, enhancements, or system migrations. It helps maintain software reliability and performance over time.

Regression Testing is a key part of maintenance testing where testers verify that recent code changes haven’t negatively affected existing functionality. Automated regression suites are often used to speed up the process.

Optimized Solutions delivered and implemented Energy management system on time and within allocated budget, providing customer with the ability to...

Download Case Study

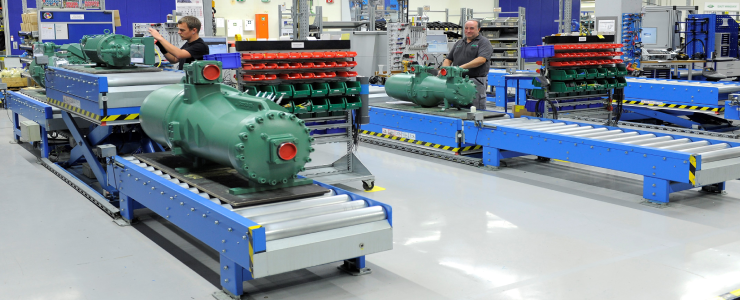

With the help of real time hardware, modular instruments and powerful ATE software, pump test facility system was design to...

Download Case Study

The ATE system is designed to ensure high-quality assurance by incorporating advanced hardware and software components.

Download Case Study