Overview

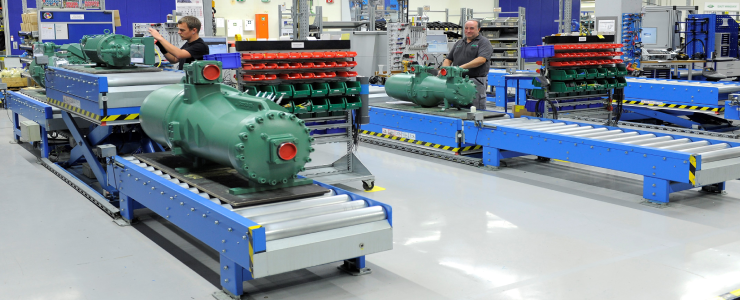

End-of-Line Testing is the final stage of the manufacturing process where products undergo comprehensive validation to check for performance, durability, and compliance with quality standards. This step is essential to identify defects, validate functionality, and ensure customer satisfaction before shipment.

We specialize in End-of-Line (EOL) Testing—a critical phase in the manufacturing process that ensures product quality, functionality, and reliability before reaching the market. Our customized EOL testing solutions are designed to enhance production efficiency, reduce defects, and maintain compliance with industry standards.

Custom Electronics

Custom Electronics

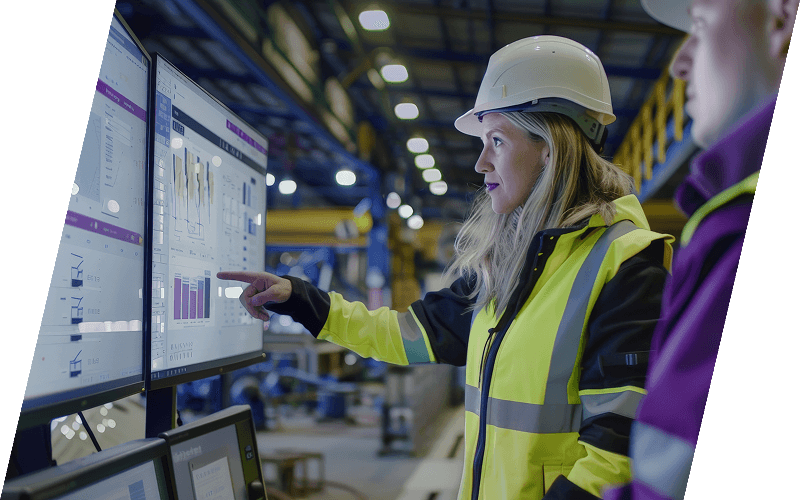

Digital Transformation

Digital Transformation

Test Measurement & Control

Test Measurement & Control

Our Products

Our Products

New Product Development

New Product Development Build To Print

Build To Print Build-to-Spec Custom Electronics

Build-to-Spec Custom Electronics Learn More

Learn More