What is a R&D Testing?

Innovative work demands attention to detail and a rigorous examination of ideas, often making it a high-cost function with uncertain outcomes. However, with the right expertise, R&D testing becomes a strategic advantage.

we ensure accurate, repeatable, and trustworthy results through cutting-edge testing solutions. Our meticulous approach focuses on optimizing every instrument and methodology to maintain a robust, reliable, and competitive testing framework.

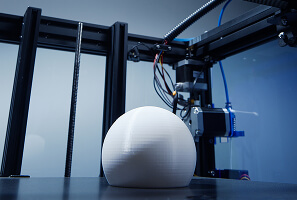

We specialize in developing new products in embedded systems, while also engaging in applied research across scientific and industrial fields. Our expertise extends to PCB testing for leading research institutions, delivering highly precise results that empower your R&D initiatives.

With our commitment to innovation and accuracy, we help you transform ideas into reliable, high-quality products, accelerating your journey from research to the market.

Custom Electronics

Custom Electronics

Digital Transformation

Digital Transformation

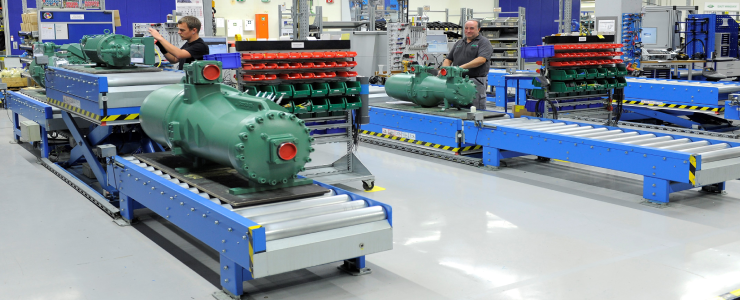

Test Measurement & Control

Test Measurement & Control

Our Products

Our Products

New Product Development

New Product Development Build To Print

Build To Print Build-to-Spec Custom Electronics

Build-to-Spec Custom Electronics Learn More

Learn More