- Home

- About Us

- Our Offerings

-

Custom Electronics

Custom Electronics

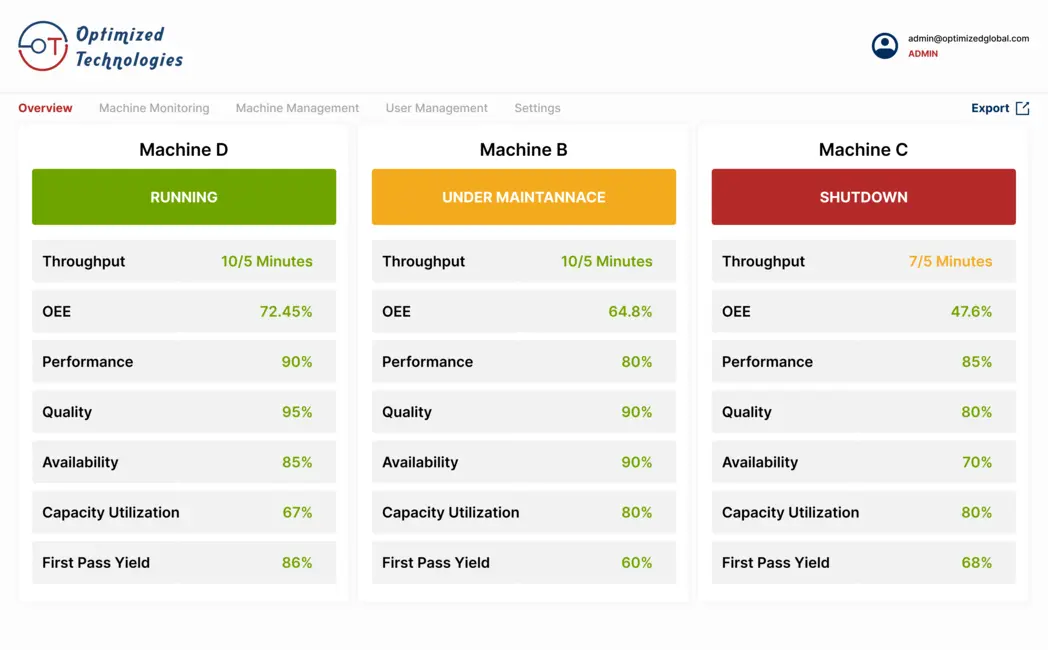

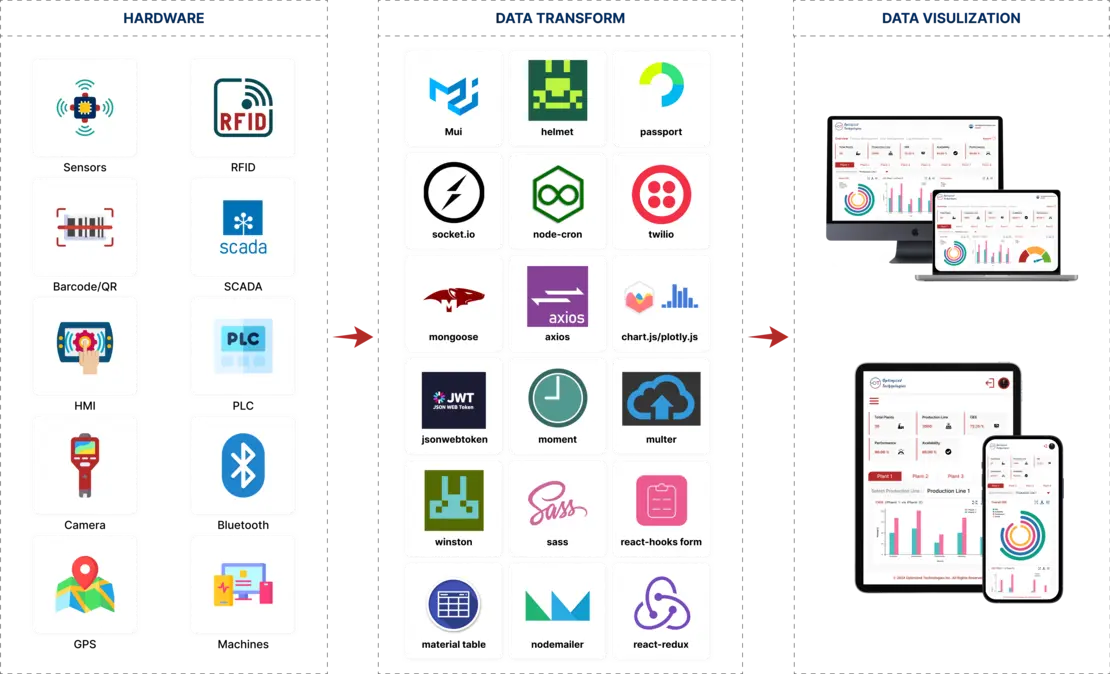

Digital Transformation

Digital Transformation

Industry 4.0 Apps

Custom Development

Deployment

Test Measurement & Control

Test Measurement & Control

Automated Test Equipment

Control Systems

Learn More

Our Products

Our Products

Our Products

- Universal Automated Test System (ATS) for Satellite Payload Power Supply

- Signal Conditioning System

- Embedded SDR – High-Performance FPGA- Based Software Defined Radio

- RF Signal Divider and LO Generation System

- RF Control System for RF Source

- OSL Embedded Controller

- Multi-ch Galvanic Isolated Signal Conditioning

- High-End NavlC Receiver (IDU System)

- Command Data Modem (CDM)

- Advanced 48ch Radar Processing System

-

- Who We Serve

- Careers

- Insights

- Contact Us

New Product Development

New Product Development Build To Print

Build To Print Build-to-Spec Custom Electronics

Build-to-Spec Custom Electronics Learn More

Learn More