Optimized Solutions presents an advanced Automated Test System (ATS) tailored for the Indian space industry. This cutting-edge solution is engineered to streamline the tuning, testing, and validation of DC-DC converters used in satellite payload power supplies.

Traditionally, characterizing these converters—each with different power ratings and specifications—has been a labor-intensive process, often requiring up to seven days per device and over a month to complete a full test cycle. Our ATS changes that.

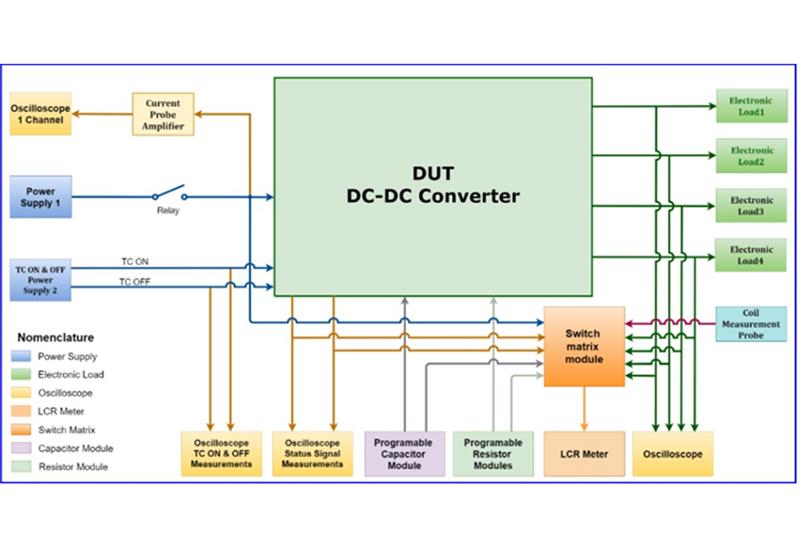

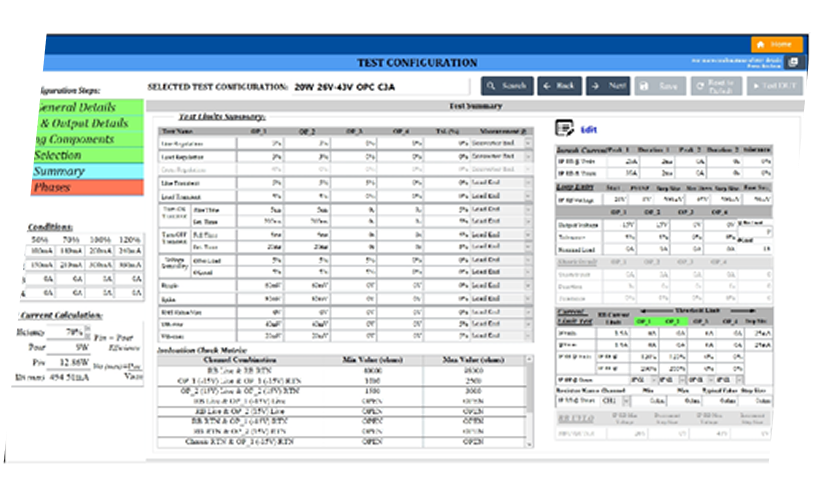

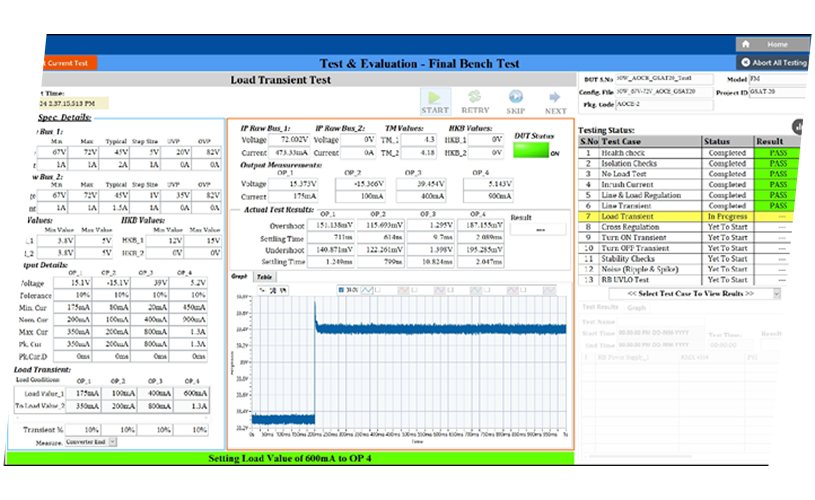

Built on the NI PXI Express platform, this solution enables high-throughput, card-level Tuning & Testing (T&T) and Testing & Evaluation (T&E) of DC-DC converters. With integrated LabVIEW-based test software, it supports simultaneous testing of two DUTs (Devices Under Test), each with independently managed tuning algorithms.

The system is designed to:

- Reduce test time by 10X compared to conventional methods

- Minimize manual intervention and eliminate human error

- Automate the entire testing lifecycle for various converter types

Highly customizable and scalable, this universal test platform ensures reliable, repeatable, and efficient testing, delivering unparalleled performance for satellite power subsystem validation.

Custom Electronics

Custom Electronics

Digital Transformation

Digital Transformation

Test Measurement & Control

Test Measurement & Control

Our Products

Our Products

New Product Development

New Product Development Build To Print

Build To Print Build-to-Spec Custom Electronics

Build-to-Spec Custom Electronics Learn More

Learn More